Telescopic boom forklift is a multi-functional equipment engineering machinery with both crane and forklift. It realizes flexible lifting and long-distance extension through the hydraulic telescopic boom, and can quickly replace the bucket, hook, digging shovel, aerial platform and other attachments, which is used in construction, agriculture, logistics and other fields. Compared with the traditional forklift, it has a larger working range and stronger adaptability to the terrain; compared with the crane, it is mobile and flexible, and can be quickly transferred to the workplace.

The core component of telescopic handlers, the telescopic boom, is made of high-strength alloy steel, and with the precise hydraulic telescopic system, it realizes an excellent working range. Under normal conditions, the boom can be lifted at a maximum elevation angle of more than 60 degrees, which ensures the stability of lifting.

Telescopic forklift is a truly multi-functional equipment, which can be called the “all-rounder” in modern engineering work. Its straight lifting height can reach more than 17 meters, which is a qualitative leap in space expansion capability compared with the working range of several meters of traditional forklift trucks.

The biggest core advantage of the extended boom forklift lies in the powerful attachment adapting system, which can complete the attachment replacement within 15 minutes through the quick-change interface design. In addition to the basic forks, the specialized tools that can be carried include:

-Material handling: Heavy-duty bucket with wear-resistant liners for loading and unloading bulk materials such as gravel and waste.

-Aerial work: standardized double guardrail working platform with a load capacity of over 200kg and built-in hydraulic leveling system to ensure the safety and stability of workers when working at height.

-Special work category: equipped with rotating function lifting arm, with laser positioning device, it can accurately complete transformer lifting, billboard installation and other difficult work.

-Site maintenance category: High-width roller brush sweeper with integrated vacuum suction system can quickly clean debris such as gravel and wood chips from construction sites.

In practical applications, these diverse configurations give the telescopic boom forklift trucks powerful task execution capabilities. In municipal engineering, a machine equipped with a snowplow attachment can clear a 2-kilometer-long city trunk road in less than an hour; in the agricultural field, a forklift equipped with a pitchfork can efficiently complete the stacking of feedstuffs. With its multi-purpose features, the forklift with extendable forks not only significantly improves operational efficiency, but also reduces the cost of enterprise equipment procurement, becoming an important core equipment in the field of modern engineering.

The performance of a telescopic boom forklift is usually considered to be dependent on the boom length, load carrying capacity and power system. In reality, the boom system and telescopic capacity, lifting height and horizontally extended working radius, as well as the high demands placed on the counterweight and counterbalance system, are all core aspects that affect its performance.

The hydraulic and drive systems of forklift telescopic booms are also of vital importance. The response speed and accuracy of the hydraulic system directly affect the operating experience, and the choice of power will also have an impact on performance. In terms of driver control and safety technology, new technologies such as four-wheel steering, automatic stability systems and on-board monitoring, as well as the working accuracy in complex terrains, are all factors that need to be considered.

When focusing on the core components such as the power system and hydraulic device of the equipment, tires, as the only contact point between the chassis and the ground, are often neglected as ordinary consumables. In fact, the performance of tires directly determines the performance of telescopic boom trucks in complex working conditions: on construction sites, wear-resistant tires can resist the sharp scrapes of gravel and steel bars and maintain stable grip; in agricultural muddy environments, deep tread can effectively remove mud and prevent slippage, avoiding equipment from getting stuck in the car; in the narrow aisles of industrial warehouses, low rolling resistance tires can reduce the resistance of steering and enhance the response speed of the operation.

These seemingly small performance differences not only affect the operational efficiency of the all terrain telescopic forklift, but also have a greater impact on the personal safety of the operators and the overall operating costs of the enterprise.

The performance of the tires of a reach truck with telescopic forks, as the sole means of contact with the ground, will affect the safety and stability of the entire vehicle’s operation. Using the right tires can effectively prevent roll and offset. By optimizing the contact performance between the tires and the ground, not only can the equipment’s passing capacity under harsh working conditions be enhanced, but also the operational safety during heavy-load handling can be ensured.

In complex environments such as construction sites, farms or forestry, ground conditions often have a large number of uneven areas. In such a case, tires with wide and deep tread designs increase the contact area with the ground, providing more robust support and performing well even under extreme conditions.

High-quality tires are the key factor to ensure the normal operation of telehandler telescopics on complicated road surfaces, and their performance is directly reflected in the traction and maneuverability. In mud, snow and other low adhesion coefficient road, ordinary tires are prone to skidding phenomenon, resulting in loss of control of the vehicle; while high-performance tires with unique rubber formula and tread pattern design, can penetrate deep into the road crevices to provide strong grip, and can drive steadily under various adverse conditions.

At the same time, tire performance braking distance and turning radius has a decisive impact. Good performance tires can significantly shorten the braking distance, allowing the forklift to stop quickly in an emergency; its excellent lateral grip, but also can effectively reduce the turning radius, so that it can be turned flexibly in a narrow space, significantly improving work efficiency and safety.

In the lifting and extending work of telescopic boom forklift trucks, the tires bear huge load pressure, and their performance is directly related to the service life of the internal parts of the equipment. When lifting heavy loads and extending the boom, the center of gravity of the vehicle body changes significantly, and the tires not only have to bear the weight of the load and the vehicle itself, but also have to cope with the impact and vibration generated.

Suitable tires are like high-performance shock absorbers, with their elastic carcasses and scientific structural design, they can effectively absorb the impact energy during operation, buffer the vibration caused by road bumps, and reduce the impact of these external forces on axles, suspension systems and transmission components.

The air pressure and quality of tires are closely related to the fuel efficiency and equipment life of telehandlers. Insufficient tire pressure will significantly increase the grounding area, resulting in a 15% increase in rolling resistance, forcing the engine to output additional power to overcome resistance, directly resulting in an increase in fuel consumption of 5% -8%. Maintaining appropriate tire pressure and using high-quality tires can reduce rolling resistance and energy consumption.

The grip and cushioning of tires are the core elements to ensure the safety of telescopic boom forklifts. In complex operation scenes, such as construction sites, the ground often exists mud and other slippery substances, high-quality tires by virtue of the rubber and tread pattern design, can firmly bite the ground, effectively preventing the forklift truck side slip out of control.

The cushioning performance is achieved through the internal structural design of the tire and rubber elasticity. When driving on uneven road surfaces, tires act as shock absorbers, absorbing and dispersing the impact from the ground. This cushioning effect not only reduces wear and tear on equipment components due to vibration, but also significantly improves operator comfort.

In soft terrains such as swamps and mud, tires with wide treads and deep tread patterns are required. These tires can reduce the pressure per unit area by increasing the grounding area to reduce the vehicle sinking; their deep tread design can effectively discharge the mud and maintain the grip.

In the face of slopes, tires with serrated tread or reinforced sidewalls can increase the friction with the slope surface to prevent slippage.When the working environment is gravel, gravel road surface, tires need to have excellent puncture resistance and wear resistance. Tires with thicker cords and cut-resistant rubber materials can resist puncture by sharp stones; special tread compound and pattern design can effectively disperse the impact of stones and reduce abrasion.

♦ Pneumatic Tires

Pneumatic tires are designed with rubber carcasses and high-pressure gas inside. This unique structure gives them excellent shock absorption performance. The air can adaptively compress and rebound with the terrain, effectively cushioning vibration and reducing equipment loss and driver fatigue. They are widely used in outdoor construction, agricultural production and transportation, mining and short-distance handling, and other complex terrain operation scenarios.

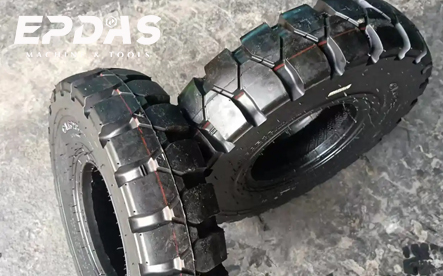

♦ Solid Tire

For workplaces that need to deal with extremely harsh environments, solid tires offer an outstanding solution with their all-rubber one-piece molding structure. The high-density material endows the tire with excellent wear resistance and puncture resistance, enabling it to withstand damage from sharp objects such as metal and glass fragments. And meanwhile, it maintains stable performance in heavy-load loading and unloading at ports and heavy cargo transportation in factories.

♦ Filled Foam Tire

Foam-filled tires are injected with polymer closed-cell foam material on the basis of traditional pneumatic tires to achieve a balance between shock absorption performance and durability. The elasticity of the foam material makes the tire maintain a cushioning effect similar to that of pneumatic tires, which can effectively absorb the bumps and vibrations in the process of driving; at the same time, the foam filling avoids the hidden dangers of insufficient air pressure and tire blowout, and significantly improves the service life of the tire.

Criteria for Selecting Tires for Telehandlers

Types of Tires

Solid telescopic boom forklift tires are the most reliable and have the strongest resistance to damage. Pneumatic tires and foam-filled tires are prone to deterioration, which can lead to more wasted time and unnecessary expenses.

Cost Effectiveness

The cost-effectiveness of tires is reflected in maintainability, longevity and reliability. Solid segmented tires are a cost-effective choice as they allow operators to easily perform maintenance, reducing downtime and costly tire repairs.

Tire Performance

Telescopic boom forklift tires with linear load distribution and special tread patterns provide superior performance and safety over common tires on the market.

Solid tires adopt an integral rubber structure design, featuring the most outstanding puncture resistance and completely eliminating the risk of air leakage. Foam-filled tires may still suffer structural damage when encountering sharp metal objects, posing a potential risk of unexpected shutdowns. In contrast, standard pneumatic tires, due to their pneumatic structure, perform the weakest in terms of puncture resistance.

Solid tires have strong resistance to cutting and impact damage, making them suitable for use in harsh environments. The ability of foam-filled tires in terms of resistance to cutting and crushing is similar to that of pneumatic tires.

Solid tires are designed with a deep wear-resistant tread, and their rubber material and thickened carcass structure provide superb wear-resistant characteristics. Compared with traditional pneumatic tires and foam-filled tires, the service life of solid tires can be extended by 2-3 times.

Foam-filled and solid tires provide good stability, but solid tires deform less under load, have sidewall holes to help absorb shock, and dissipate heat more efficiently. EPDAS telescopic boom forklift tires feature a new, non-directional tread pattern with a continuous center block and higher tread occupancy, which reduces wear and vibration.

Solid tires provide excellent stability when working at height thanks to their all-rubber construction, which is virtually deformation-free and ensures that the forklift stays smooth over complex terrain. In contrast, pneumatic tires are susceptible to changes in air pressure and pose a safety risk.

High-quality tires, with their special grip and wear resistance, offer excellent grip and wear resistance. Excellent anti-slip performance can reduce the relative sliding between the tires and the ground, ensuring smooth operation of the telescopic boom forklift during acceleration, steering and braking, and significantly increasing the moving speed.

Adapted high-quality tires can effectively reduce energy consumption by 15%-20%, reducing the burden on the power system, significantly saving operating costs and extending the service life of the equipment.

Severely worn tires have a shallower tread depth, significantly reducing their grip and drainage performance. Telescopic boom forklifts are prone to slipping and losing control when traveling on uneven roads. Regularly checking the wear of tires and promptly replacing those that are severely worn are necessary measures to ensure safety.

Why are Solid Rubber Tires Recommended for Telehandlers?

Solid rubber tires are a better solution to the problem of telescopic boom trucks stopping due to flat tires, significantly improving the efficiency of the equipment. Compared with pneumatic tires, the one-piece solid rubber structure eliminates the risk of flat tires, and even if it is damaged by foreign objects, it can still continue to work and ensure normal operation.

High-quality solid rubber tires have good elasticity, which can absorb ground vibration to a certain extent, reduce the impact of the mechanical transmission system, and improve handling comfort and stable operation of the equipment. High-quality solid rubber tires have good elasticity, can absorb ground vibration to a certain extent, reduce the impact of the mechanical transmission system, enhance control comfort and stable operation of the equipment. Long life cycle, do not need frequent inflation and maintenance, long-term use can effectively reduce operation and maintenance costs.

To extend the service life of the tires of telescopic boom forklifts, it is very important to conduct a pre-operation inspection. Operators need to incorporate tire inspection into their daily routine to identify potential problems that could lead to equipment blowouts and other phenomena. It is necessary to check whether there are any abnormalities such as cracks or cuts on the tires or treads.

In addition to checking your tires daily, you also need to check your tire air pressure. Low air pressure can lead to a blowout, and as the temperature changes, so does the air pressure in the tire. You also need to make sure that you do not over-inflate your tires. Over-inflation can lead to premature tire tread wear.

When it comes to actual construction, some drivers try to load as much cargo as possible on each trip, but this can be very damaging to your tires, especially over long distances. Only load heavy equipment according to the weight rating of the tires. If this weight rating is exceeded, there is a risk of a tire blowout, causing irreversible damage.

If tires are not rotated regularly, the weight distribution will be unbalanced, resulting in inconsistent tire wear rates – one may have intact tread patterns while another is already on the verge of replacement. By rotating, the weight distribution can be kept uniform, thereby helping to extend the service life of the tires.

When choosing a telescopic fork truck, performance, stability and durability are core considerations that cannot be ignored. These qualities are directly related to work efficiency, operational safety and the long-term cost of the equipment, which is the key to guaranteeing the smooth progress of all kinds of projects.

As a professional manufacturer in the field of concrete and construction machinery and equipment for many years, EP Machinery has more professional and tough technology. EP Machinery is not only committed to building high-performance telescopic forklift trucks to ensure that the equipment can maintain strong power and stable performance in complex scenarios, such as heavy-duty handling and overhead work, but also provides reliable quality and adaptable solutions to a variety of working conditions to address the problem of tires.

EPDAS always focuses on the actual working needs of customers, providing a complete system of procurement, professional technical guidance and comprehensive service guarantee. Customers do not need to worry about equipment and accessories fitment problems, but also in the use of the process to obtain timely technical support and maintenance services.

Conclusion

The efficient operation of telescopic handlers relies heavily on well-matched tires. Selecting the appropriate tire type based on terrain, load, and working conditions is crucial for operational efficiency, safety, and equipment longevity. Understanding equipment requirements, mastering tire characteristics, and performing regular maintenance are key to maintaining optimal performance.

During the selection and use process, understanding the requirements of the telescopic boom forklift, mastering tire characteristics and performing regular maintenance are key to ensuring that the equipment always performs at its best. Contact EPDAS to learn more about telescopic boom truck performance and more!