Moving, lifting and placing heavy loads is a core challenge faced on a daily basis in all types of operational scenarios, including construction, agriculture and warehousing. Sometimes steel needs to be transported to tens of meters high, sometimes farm machinery has to be transferred in muddy farmland, sometimes goods have to be stacked in narrow warehouses – complex scenarios that are often difficult to cope with with ordinary equipment.

Telescopic boom forklift is by no means an ordinary operating tool, it is the key equipment that can improve the safety of operation and adapt to the needs of multiple scenarios, and has long been an indispensable presence in many industries. Next, we will talk about its working principle, core advantages, applicable scenes, and how to select the right equipment.

Telescopic boom forklift, also known as telescopic boom truck, telescopic boom tool truck, the core function is to lift, carry and accurately place heavy objects. Its most notable feature is the telescopic boom, a design that allows the equipment to extend upward to lift heights and forward to expand the horizontal operating range, breaking the operating limitations of traditional handling equipment.

The adaptability of the equipment is also reflected in the accessories and accessibility. By matching different attachments such as forks, hoppers, hooks and platforms, it can cope with diversified operational needs. Meanwhile, most models are equipped with four-wheel drive and all-terrain tires, so that they can run smoothly even on rugged mountain roads, muddy farmland or uneven construction sites.

This design fundamentally makes up for the shortcomings of basic material handling equipment. Traditional tools often have a single function, while the telescopic boom forklift truck integrates multiple functions, allowing a single piece of equipment to solve a variety of problems such as lifting, handling, and working at height, which is one of the core reasons why it can become a must-have for construction sites.

Advantages at a glance, complex scenes easy to manage

Ordinary forklifts are only suitable for storage and short-distance handling, telescopic boom forklift breaks through the scene limitations by virtue of three core advantages:

It also has the advantage of multi-functional integration – integrating the functions of forklift, crane, loader and work platform, replacing multiple traditional tools with one machine, and significantly reducing the procurement/rental cost and the pressure of site storage.

Double Upgrade of Safety and Efficiency

Safety Guarantee: Excellent stability performance, smooth positioning for high place operation, significantly reducing the risk of heavy load shaking and equipment tipping over; meanwhile, reducing the number of equipments, avoiding the collision and scraping hidden dangers brought by frequent switching.

Efficiency multiplier: construction sites, for example, can be synchronized to complete the loading and transportation of materials, personnel work at height (installation/maintenance), without the need for cross-equipment deployment and waiting, significantly accelerating the overall construction progress.

Construction industry: the backbone of construction site operation, and it can work smoothly in compact sites.

As the core equipment of construction sites, telescopic boom forklift trucks can easily carry out the dual tasks of material handling and aerial work. In high-rise residential construction, heavy materials such as bricks, steel beams and timber can be lifted by it with a single key and extended over a long distance, and then sent to the designated floors directly without the need to build complex transportation channels; in plant construction, the addition of a manned work platform can replace the aerial work trucks, allowing workers to arrive at the high place to complete the installation and maintenance safely. Case: small urban construction site construction, space is narrow large equipment can not enter, small telescopic boom forklift with flexible steering, in the narrow area of free movement, the smooth completion of material handling and aerial installation, the work period than the original plan to shorten 1/3.

Agriculture and farming: a good helper in farming, all-terrain adapted to the countryside scenario.

Telescopic boom forklift for the busy season of agriculture is the agricultural production of the “efficiency bearing The forklift is the “efficiency bearer” of agricultural production in the busy season of agriculture. During harvest time, fast loading, stacking, transporting hay straw, avoiding material moisture deterioration, significantly reducing the intensity of manual handling; sowing, fertilizer stage, easy lifting and carrying planters, sprayers and other heavy agricultural machinery, to solve the problem of manual movement. In the breeding scene, placing feed troughs, water storage tanks, and building temporary fences can be done with one piece of equipment, making livestock and poultry management more convenient. Case: In rural hilly farmland operation, ordinary handling equipment is easy to get stuck and unstable, telescopic boom forklift, with all-terrain performance, works smoothly in undulating terrain, and hay loading efficiency is 2 times higher than the traditional way.

Manufacturing and Warehousing: Optimize the loading and unloading process and improve the utilization of warehouse space.

The “space magician” of manufacturing workshop and warehousing depot, specializing in pallet cargo loading and unloading, stacking problems. Easily load the goods onto the truck, or stack the pallets to the high shelves, fully tap the vertical storage space, doubling the utilization rate of the warehouse; inventory replenishment, goods shifting, the operation is flexible, fast moving, reducing the handling waiting time, to adapt to the high-frequency loading and unloading needs of production warehouses. Case: a production enterprise warehouse, the introduction of telescopic boom forklift, goods stacking height increased to 8 meters, storage space increased by 60%, the efficiency of material replenishment increased by 50%, to completely eliminate production stoppages due to untimely supply of materials.

Gardening and Maintenance: A Powerful Tool for Specialized Tasks, Safe, Efficient and Cost Saving

The “multi-faceted hand” for gardening and grounds maintenance easily solves all kinds of specialized problems. When trimming and removing trees, with the grapple/pruning attachment, it can reach high branches without building scaffolding, safe and efficient; when cleaning up the site, with the sweeping attachment, it can quickly collect debris, leaves, and construction debris, and clean up the site with a single click to meet the safety and compliance requirements. Case: urban park greening maintenance, telescopic boom forklift flexible shuttle in the forest, walkway, complete the high branch pruning and leaf clearing, 1 equipment instead of 6 manual labor, single day operation area increased 3 times.

First, clarify the core requirements of the operation

Maximum lifting weight: determine the heaviest material in daily life, choose a model slightly higher than the maximum load, to avoid overloading equipment life and safety hazards;

Lifting height: choose a high lifting model for high-rise construction, and choose the height of shelves in combination with the use of warehouses;

Horizontal operating radius: choose a model with a long horizontal extension distance for cross-barrier and long-distance discharge, to reduce the number of times of equipment movement;

Space of the operation site: Narrow space (urban construction site / indoor warehouse) choose a small turning radius of the compact models, outdoor open space can choose a large size, high stability models.

Keep an eye on the key parameters of the equipment

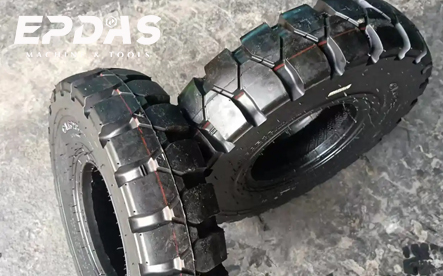

Tire type: pneumatic tires are suitable for farmland / mountain and other soft ground; foam-filled tires are suitable for ordinary construction sites, not easy to burst tires, but the sidewalls are easy to damage; solid tires are the most durable, suitable for large warehouses and parks, frequent transfer of materials, and long-distance driving scenarios;

Engine power: 74 hp below the section of the maintenance is simple, no special maintenance to meet the ordinary operation; 74 hp or more models with more power, suitable for steep slopes, heavy lifting, long time and high intensity. The engine power: 74 hp or less is simple to maintain and does not require special maintenance to meet common operations; 74 hp or more is more powerful and suitable for steep slopes, heavy lifting, and long-time high-intensity operations, and requires regular maintenance to meet emission requirements.

Suitable attachments can make telescopic boom forklift trucks more comprehensive in function and adapt to more segmented scenarios.

Hopper Attachment

Ordinary hopper: suitable for loose materials such as soil, wood chips, gravel, etc.; hopper with grapple: to deal with irregular heavy objects and prevent falling; multi-functional hopper: detachable design, both loading, transportation, dumping, grappling function, but also can level the ground, spreading materials, and is highly practical.

Load Attachment

Standard Forklift: suitable for regular palletized goods, easy to operate; Side Tilting Forklift: to keep the load stable in uneven terrain, and can pick up/put down materials that are not level; Side Swinging Forklift: the load can be shifted to the center at 50-90 degrees on both sides, suitable for the narrow space; Forklift with Adjustable Fork Distance: the distance is adjusted by power, so that it can be used for different sizes of pallets without getting out of the car to improve the efficiency.

Truss Arm and Hook

Enhance the extension capacity of the equipment, the truss arm is available in various lengths and part of it is adjustable, suitable for lifting steel girders and trusses in the construction industry; Truss arm with winch: the boom can not move up and down to lift heavy loads linearly in the scenario and is suitable for precise work in narrow space.

Specialized attachments (suitable for specific industries)

Forklift work platform: manned high work (such as building maintenance, equipment installation); Pipe grab: special for oil and gas industry, safe handling of long pipes and poles; Sweeper: construction site, park debris cleanup, debris can be collected to the hopper; Auger: digging tree holes, pole pits, auger diameter of 6-36 inches, adaptable to different hole diameters.

telescopic boom forklifts have been proved to be necessary in many industries: multi-functionality replaces multiple traditional equipment and reduces investment costs; all-terrain adaptation eliminates the need for scene-by-scene purchasing; and stable performance + integrated operation reduces risk, reduces linkage, and improves efficiency.

For construction contractors, farmers and warehouse managers, renting or purchasing the right telescopic boom forklift is a long-term guarantee of operational efficiency and safety. Matching models and attachments as needed maximizes value.

It is by no means a dispensable luxury, but a necessary tool to break the limitations of traditional equipment, enhance operational capacity and reduce comprehensive costs, and has become the core configuration of modern operational scenarios.