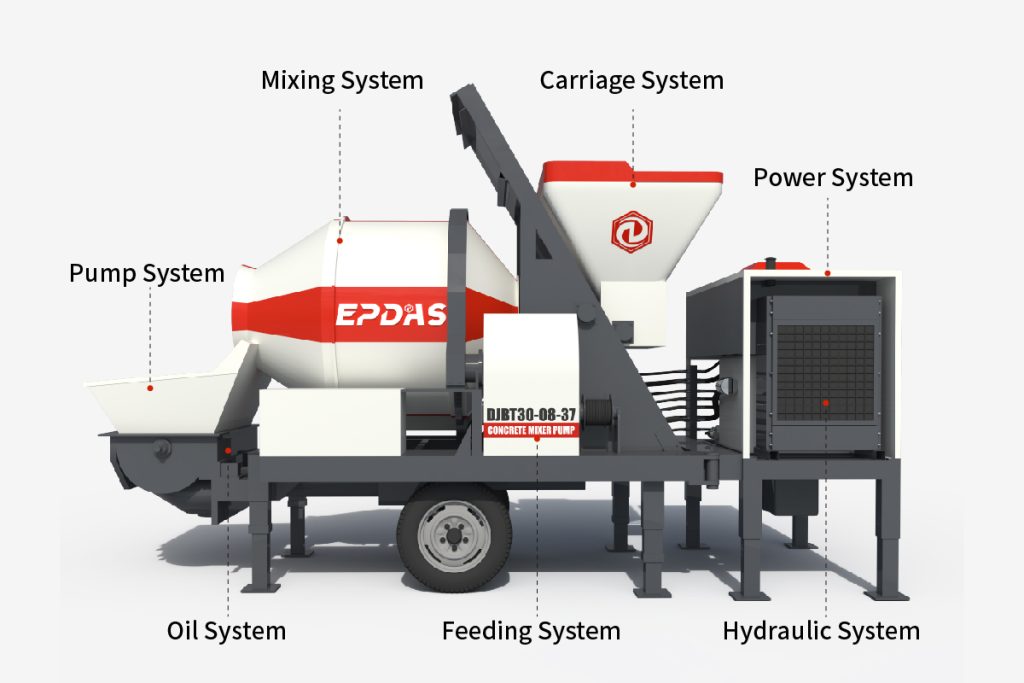

In 2025, concrete mixer with pumps are becoming the new standard equipment on modern construction sites. This equipment integrates the two major functions of “concrete mixing and production” and “high-pressure pumping.” The integrated design saves over 50% of equipment space and enables the entire process of “on-site mixing, immediate pumping, and precise pouring,” boosting construction efficiency by up to 40%.

The traditional “mixer truck + pump truck” combination is increasingly unable to meet modern construction needs. The most popular concrete mixing and pumping machines in 2025 are increasingly incorporating automated features, including advanced control systems, remote information processing, and integration, enabling operators to remotely monitor and control the mixing process.

Through intelligent upgrades, optimized power systems, and customized services, these challenges have been addressed. Based on 2025 market trends and the features of popular models, professional purchasing recommendations are provided.

In urbanization construction, construction of city roads, cross-river bridges, high-rise residential buildings, and industrial facilities continues to grow. These construction projects are characterized by tight schedules and high construction intensity. The concrete mixer and pumps feature high efficiency and flexibility. Its compact design and ability to quickly transfer construction sites better meet the requirements of narrow urban areas.

The refinement of division of labor in the construction industry has driven the growth of the number of small and medium-sized construction enterprises. These companies prefer to purchase “mixing + pumping” integrated equipment, which can reduce fixed asset investment by over 35% compared to traditional separate equipment configurations, while also lowering daily operational costs by approximately 30%.

Rural infrastructure projects have seen a surge in demand for versatile construction equipment. Cement mixer with pumps are highly popular due to three key advantages: first, their modular design facilitates transportation and installation; second, diesel-powered models are suitable for regions with weak power infrastructure; and third, simplified operating procedures reduce reliance on specialized technical workers. In Southeast Asian and African markets, the annual growth rate of such equipment has been increasing year by year.

By 2025, the intelligent development of concrete mixing and pumping machines has become the core of competition. The models are generally equipped with advanced control systems and remote monitoring functions, allowing real-time viewing of equipment operation data through mobile devices – including stirring speed, pumping pressure, fuel consumption/power consumption, etc.

EPDAS’s portable concrete mixer with pump intelligently adjusts the water-cement ratio and admixture dosage by continuously monitoring critical parameters such as pumping pressure and environmental temperature, ensuring the concrete remains in optimal working condition throughout long-distance transportation.

When environmental temperature fluctuations reach 5°C, the system automatically activates the mix ratio adjustment mechanism; when pumping pressure fluctuations exceed 15%, the intelligent compensation function immediately responds. Construction efficiency has improved by 22%, providing a reliable guarantee for the efficient progress of engineering projects.

The concrete mixing and pumping machine features a liftable hopper design, which uses a hydraulic lifting system to directly convey aggregates into the mixing drum, eliminating the need for auxiliary equipment such as loaders.

The dual-shaft mixer and pumping mechanism work in tandem to achieve uninterrupted operation throughout the entire “feeding-mixing-pumping” process, effectively avoiding work interruptions common in traditional construction methods, resulting in an overall construction efficiency improvement of over 40%.

The DJBT50-10-85 model from EPDAS achieves a continuous mixing capacity of 48 m³/h, increasing daily pouring volume by 25% in highway bridge construction. This helps construction teams reduce investment in auxiliary equipment and significantly lower construction costs.

In response to the complex situation of “occasional power outages and emission restrictions” at some construction sites, dual-power models (diesel + electric) have become a more popular choice. Using electric mode in areas with power grids reduces costs, while using diesel mode in remote areas ensures construction. This flexibility makes them highly favored in multi-scenario projects.

Concrete mixer pumps are available in two main types: electric and diesel. The electric model is powered by three-phase industrial AC power, but for some customers, it is not convenient to use. Therefore, most customers will choose the diesel-powered concrete mixing and pumping integrated machine. As long as there is sufficient fuel, it can work normally anywhere.

Compared to using a separate concrete mixer and concrete pump, this all-in-one machine saves on equipment space and costs while significantly improving work efficiency.

Application Scenarios: Construction in areas without power supply or remote regions

Core Advantages:

✓ Completely independent of the power grid

✓ Adaptable to extreme environments from -20°C to 45°C

✓ Equipped with heavy-duty tires for easy relocation

✓ Ideal for mobile construction projects such as road and water conservancy projects

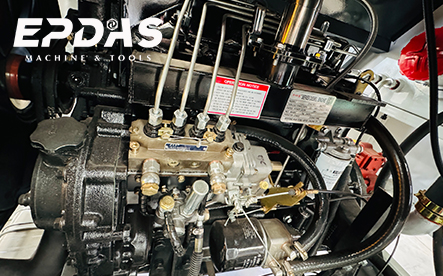

EPDAS DJBT40-10-82 Diesel Model: Equipped with a 6-cylinder turbocharged engine, mixing capacity of 40m³/h, pumping pressure of 10MPa, and maximum delivery distance of 250 meters. It operates stably in construction projects, with sales growing by 60% year-over-year in 2025.

Power system: High-power industrial power supply drive

Applicable scenarios: Fixed construction sites in cities

Core advantages:

✓ Operating costs 40% lower than diesel models

✓ Noise < 70 decibels, zero emissions

✓ Intelligent electronic control system for more precise pumping

✓ No daily maintenance of diesel engines required

EPDAS EJBT30-08-37 Electric Model: High-power industrial electric drive, mixing capacity of 30 m³/h, pumping pressure of 8 MPa. It performed exceptionally well in a subway supporting project in a provincial capital city (with noise levels as low as 65 decibels and zero complaints), becoming the top choice for project procurement.

The concrete mixing pump, through its compact design, significantly reduces the floor space it occupies. At the same time, it eliminates the process from unloading concrete from the mixer truck to the pump truck’s hopper, thus avoiding material waste and time loss.

Compatibility with multiple concrete types: It can not only mix and pump ordinary concrete, but also handle mortar and lightweight concrete, meeting the needs of different projects.

Flexible power switching: There are two drive models, diesel and electric. In areas with power grids, the electric mode is adopted. When grid access is difficult, it switches to diesel mode to ensure uninterrupted construction.

Chassis options: Choose a wheeled (convenient for road transportation) or tracked (muddy/mountainous terrain) chassis based on the terrain to ensure the mixer pump’s passability in various sites.

Concrete mixing and pumping integrated machines generally adopt one-click automated operation: Just set the mixing parameters and pumping targets, and the equipment can automatically complete the entire process of feeding, mixing and pumping. It is equipped with a touch screen that can display real-time data for convenient operation.

The key components of the concrete mixing pump have a 50% longer service life than the original equipment, fundamentally reducing equipment downtime for maintenance and lowering long-term operating costs.

The core S valve is made of high-chromium alloy material, significantly enhancing its wear resistance and enabling it to withstand continuous wear during high-intensity construction.

The vulnerable parts such as the stirring blades and wear-resistant rings are equipped with advanced configurations. One person replacement can be completed quickly, ensuring the equipment returns to operational status promptly.

Comprehensive optimization from core components to wear-prone parts ensures the equipment maintains stable performance during long-term, high-frequency construction, providing reliable and durable support for various engineering projects.

| Item | DJBT40-10-82 |

| Theoretical Concrete Pumping | 40 m³/hr |

| Max. Concrete Pumping Pressure | 10 MP |

| Main Engine | Diesel Engine: WEIFANG 82KW |

| Main Oil Pump | KAWASAKI 112 |

| Theoretical Pump Distance | Height: 60 m

Length: 250 m |

| Aggregate Lifting Volume | 500L Per Hopper |

| Controller | Wireless / Cabinet-buttons |

| Machine Weight | 5300 kg |

| Length of Concrete Pipe | 1000 mm |

Diesel Engine

This concrete mixing and pumping machine uses a high-power diesel engine (82 kW) to provide powerful power and is suitable for construction sites without electricity or with unstable power supply. The engine and hydraulic system are efficiently matched to improve overall work efficiency.

The device uses a forced mixing system with dual mixing blades. The mixing shaft drives the dual mixing blades to rotate via gear transmission, enabling rapid mixing of aggregates and cement of various particle sizes to ensure the uniformity of concrete and the quality of the output.

High-pressure double-cylinder hydraulic drive, equipped with intelligent S-valve reversing technology, maximum pumping pressure of 10MPa, and a delivery rate of up to 40m³/h. Made of high-chromium alloy wear-resistant material, combined with an automatic lubrication system, to ensure stable delivery of various types of concrete.

Equipped with a main control panel and intelligent control module, it supports remote control and manual operation switching. Key fault alarms, pressure display, oil temperature monitoring, and other functions are all displayed to ensure safe and reliable equipment operation.

Bucket Elevator System

The bucket drive design automatically lifts materials, with dual hydraulic cylinders lifting synchronously for smooth and reliable operation, enabling uninterrupted concrete feeding and greatly improving construction efficiency.

A single unit integrates mixing and pumping functions, significantly reducing procurement costs compared to traditional separate units. Its core performance (such as pumping pressure and durability) meets the mainstream standards of other mechanical equipment. In addition, the high-configuration 82kW diesel engine is adaptable to meet construction budget requirements and can be used for many years.

With a mixing capacity of 40m³/h, it perfectly meets the needs of small and medium-sized projects, avoiding both cost waste due to excess capacity and delays due to insufficient capacity. The mixing capacity of the DJBT40-10-82 integrated machine can be precisely matched to the daily concrete usage, efficiently completing the concrete pouring work for each building.

The equipment is equipped with thickened dual-tire chassis, which is easy to move. The body length can be transported by ordinary trailers, quickly transported to various project sites to carry out construction, improving the overall construction efficiency. In addition, the overall body center of gravity is low, making it more stable during operation.

The button layout is simple and intuitive, with clear operating logic, enabling quick start, stop, and function switching. It features a bilingual Chinese-English switching mode that is simple and easy to understand. It also supports both remote control and manual operation modes.

In 2025, an overseas client of EPDAS undertook a highly challenging 30-kilometer rural road paving project. After thorough evaluation, two DJBT40 diesel-powered concrete mixer pump units were selected for the construction.

Project Challenges:

Geographical Dispersion: The project sections were fragmented, making it difficult for traditional centralized construction methods to cover the entire area. Additionally, the construction site was located in a remote area with no stable power grid access. The project required the completion of 80 cubic meters of concrete pouring daily, imposing stringent demands on the mixer pump’s performance metrics.

Solution:

Based on the location of each construction section, the DJBT40 was placed nearby to achieve integrated “on-site mixing + immediate pumping” operations, directly delivering concrete to the road surface. The diesel power system used is capable of operating in environments without electricity. Furthermore, the traditional method of “centralized production at a mixing plant + long-distance transportation by tankers” was not used, reducing concrete loss and waiting time during transportation.

Final Achievements:

The flexible working performance of the mixer pump machine, the construction period was compressed from the originally planned four months to three months, and the project was completed one month ahead of schedule. The DJBT40 diesel model’s mobile convenience and high-efficiency production capacity advantages have effectively improved local infrastructure.

Power supply: Is there an adequate power supply? Diesel models are preferred as they can be used at any time in areas without a power supply.

Terrain and transportation: In mountainous or muddy areas, choose thickened dual tires and a wheeled chassis for easier transportation.

Space restrictions: In narrow sites, pay attention to equipment dimensions to ensure they can enter the construction area.

Concrete volume: If the daily demand is ≤50 cubic meters, choose medium and small-sized models such as DJBT40 or DJBT30. If the volume is ≥80m³, large-scale equipment with DJBT50 or above should be considered.

Concrete type: Ordinary concrete is suitable for most models. Please confirm whether the equipment supports it (some models require a specially configured pumping system).

Conveying distance/height: For high-rise buildings or long-distance conveying, attention should be paid to the pumping pressure (the higher, the more suitable).

Prioritize brands with after-sales quality guarantees (EPDAS provides reliable after-sales service) to ensure timely repairs. Inquire about the warranty period and whether operator training is provided.

Customized Concrete Solutions for Your Project

Among the various competitive advantages in the market, customized services have long been the core of brand competitiveness. Taking EPDAS as an example, its customized options for concrete mixer pumps cover four dimensions:

♦ Structural and Functional Optimization Customization

Based on customer operating habits and site constraints, we offer customized equipment dimensions suitable for narrow spaces or special access conditions; customized operating interfaces can be selected with semi-automatic or manual operating systems. Additional functional customization is also available.

♦ Brand and Visual Customization

EPDAS also supports brand customization to help customers create a unique equipment image, including partial color painting and instrument language switching.

♦ Professional and Transparent Service Process

Our customization process is transparent and efficient, with every step—from communication, design, manufacturing, to delivery and training—strictly controlled by a professional team. We provide design proposals and technical drawings, proceed to customized production after order confirmation, ship after testing and inspection, and offer global transportation support, free usage training, and technical support.

Standardized equipment often fails to meet specific operational requirements, while customized solutions can address the needs of most customers. The addition of a high-capacity design can improve the overall efficiency of the project and avoid cost waste caused by over-configuration.

Concrete mixer with pumps offer an economical, versatile, and reliable construction solution for small to medium-sized concrete projects. DJBT40-10-82, with its superior performance and high cost-effectiveness, has become an ideal choice for small and medium-sized projects. And for larger construction projects, higher-spec models or customized solutions can deliver greater value.

Whether you are a contractor, construction company, or distributor, the concrete mixing and pumping machine is a reliable choice. Please contact us for more information about the equipment.