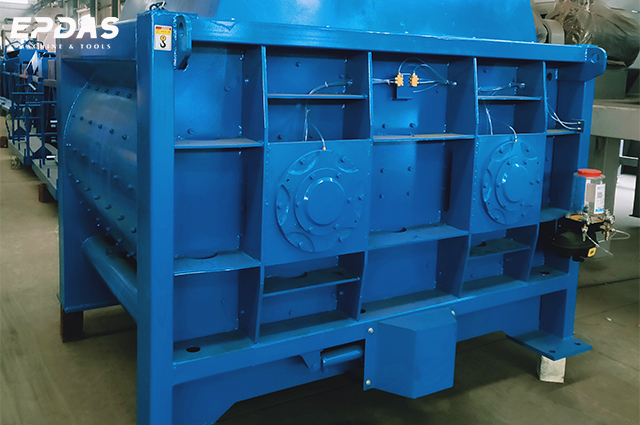

HZS90Q Concrete Batching Plant

HZS series concrete batching plant (belt type) is composed of the mixing machine, material weighing system, material conveying system, material storage system, control system and other subsidiary facilities. The concrete mixing plant enjoys the benefits of large transport distance, high efficiency and low failure rate. With good mixing effect for dry, rigid, plastic and all kinds of concrete proportion, stationary concrete batching plant is widely used in the long duration and site-focused large and medium hydropower project, bridges and other construction projects etc.

Production Types

Mixer Types

Name:

HZS90Q Concrete Batching Plant

Theoretical productivity:

90m3/hr

Feeding mode:

Belt conveyor