It is not easy to establish a firm foothold in the construction industry. This industry requires a great deal of time, patience, money and equipment. Construction companies have the responsibility to turn people’s dream of owning a house into reality. They are the pillars of large buildings and residences, and this process is highly dependent on efficient construction equipment. Among them, the concrete mixing plant, as a core production facility, directly affects the project progress and construction quality.

The core function of a concrete batching plant is to measure and mix cement, sand and gravel, water and chemical additives in the designed proportion through an automated control system, and produce concrete mixtures that meet the engineering needs. The batching plant can ensure that the uniform performance of concrete materials and other aspects meet the specification standards, and produce high-quality concrete for construction projects. The continuous and stable operation of the mixing plant is an important condition for ensuring the construction progress and structural safety, and its production efficiency directly affects the control of the project progress.

As one of the important equipments in construction projects, concrete mixing plant equipment, also known as concrete mixing plant, can efficiently mix raw materials such as water, sand, air, additives, fly ash, slag, soot, silicon dioxide, cement and aggregate (gravel, rock, etc.) together to make high-quality concrete, so as to provide solid and reliable foundations for the construction projects, and play an important role in the whole project. Whether it is a high-rise building in the city, whose foundation is poured up to tens of meters deep; or a rugged road between the countryside, the paving of each road surface, are inseparable from the supply of concrete.

At present, the market dominates the mixing plant is mainly divided into two categories, namely, fixed concrete mixing plant and mobile concrete mixing plant. These two kinds of mixing plants each play different superior functions and advantages.

In engineering projects, if the type of concrete batching plant is not precisely selected based on actual needs, it may trigger multiple risks ranging from a decline in construction efficiency to cost overruns and even substandard project quality. Therefore, systematically sorting out the core differences between fixed and portable batching plants in terms of capacity adaptability, site dependence, and flexibility in site transfer is a key decision-making basis for ensuring project progress, controlling construction costs and achieving quality goals.

The fixed concrete batching plant is fixed in one location and is specially designed for long-term construction projects that require a large and stable supply of concrete. It is highly suitable for large-scale infrastructure projects such as highways, giant dams or large-scale commercial developments that require long-term and frequent supply of concrete. These devices adopt advanced mixing technology and can efficiently produce large quantities of concrete, usually with higher precision and customization.

Due to the need for a large amount of ground engineering, public facilities and equipment installation, the construction of these factories is more complex and expensive, but they have the advantage of economies of scale in production and are ideal choices for concrete construction buildings.

These plants are more complex and expensive to build due to the extensive groundwork, utilities and equipment installation required, but they offer the advantage of economies of scale in production and are ideal for concrete construction buildings.

Mobile concrete batching plant, also known as portable concrete mixing plant, is a kind of equipment to move concrete production to the work site as needed. Mobile concrete batching plant has smaller size, easy to transport, adaptable and flexible, easy to transfer to the job site, and wide range of use.

These mixing plants are designed for mobility and are ideal for projects that are spread across different locations or where the demand for concrete is erratic. Small construction sites, rural projects, or temporary works construction operations where flexibility is essential.

Portable concrete mixing plants are less costly, easier to set up, require minimal basic work, and can be quickly assembled and disassembled than fixed ones. Although they may produce smaller batches of concrete, they offer the ability to adapt to the constantly changing project requirements.

Different Concrete Batching Plants Suitable for Your Construction

In the practice of construction engineering, the selection decision of concrete mixing plant directly affects the construction progress, project quality and project economic benefits. The current engineering construction shows a diversified development trend, fixed and mobile mixing plant as the two main equipment, each has its own advantages in terms of capacity, flexibility, site requirements and applicable scenarios.

Fixed type is suitable for long-term, high-volume, fixed location projects; mobile type is suitable for short-term, decentralized, flexible transfer projects. Only by understanding the difference between them, according to the needs of the project, scientific selection, reasonable configuration, in order to provide a strong guarantee for the smooth progress of the project.

Stationary concrete batching plants are large, fixed installations, usually built on permanently installed foundations. These plants can produce large quantities of concrete continuously, and stationary concrete batching plants are stable and efficient, with a low failure rate and a long service life.

Stationary concrete mixing plant is mainly divided into two types: belt-type and bucket-type according to the different ways of material conveying. Belt-type stationary mixing plant adopts continuous conveying belt conveyor to transport aggregate from batching machine to mixing machine, which is suitable for the construction of large quantity production with smooth operation.

On the other hand, bucket type stationary mixing plant lifts materials vertically to the mixer through elevating bucket, which is relatively more compact and occupies a small area, and is suitable for the projects with limited site or not high requirement on production. When a high concrete output is required for a long time (usually tens or even hundreds of cubic meters per hour), choosing a fixed concrete mixing plant is the best option.

For instance, a large residential complex, bridge or highway project is under construction for months or years and usually relies on fixed factories to ensure a continuous supply of concrete. The time required to set up a fixed mobile mixing plant is longer than that for a mobile concrete mixing plant.

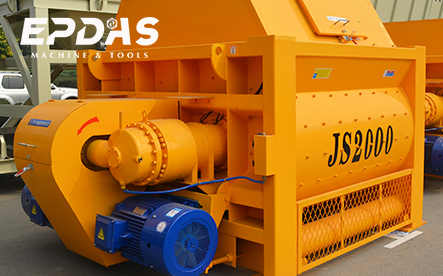

Mixing machine: Mainly double horizontal shaft forced mixer (JS1000-JS4000 models), some large-scale use of vertical shaft planetary mixer. The mixing shaft and blades are made of high-strength wear-resistant materials, which can deal with various kinds of concrete, such as dry and hard, fluid and so on.

Material Weighing System

Aggregate weighing: Independent weighing hopper with bin design, with high-precision sensors, accurately weighing different specifications of sand and gravel according to the ratio (error ≤ ±1.5%).

Powder weighing: Cement, fly ash, etc. are measured separately, and unloading is controlled by pneumatic butterfly valve, error ≤±1%.

Liquid weighing: Water and additives are transported to the special weighing hopper through metering pump, supporting synchronous measurement of multiple groups of additives.

Material Storage System

Aggregate silo: Steel structure or reinforced concrete silo (50-500 tons capacity), divided into 3-6 compartments for storing different sizes of sand and gravel, with vibrating feeder to prevent clogging.

Cement silo: Cylindrical steel structure (50-1000 tons capacity), with material level meter and arch breaker to avoid lumping of powder.

Admixture silo: Sealed tank (1-10 tons capacity), divided into silos according to type, with mixing device to prevent sedimentation.

Control system: Industrial computer + PLC control cabinet + touch screen, fully automatic production, support data traceability and remote monitoring.

Attached facilities: Pulse dust collector (to control dust), air compressor (to drive pneumatic valves), high-pressure cleaning system (maintenance equipment), etc.

Scenario: Long-term projects such as expressways, railways, Bridges, tunnels and water conservancy projects.

Advantages:

High capacity: Equipped with multiple mixing mainframes and large-capacity storage silos to meet large-scale concrete demand.

Strong stability: Fixedly installed near the construction site, reducing transportation distance.

High degree of automation: Integrated batching, mixing, conveying and other whole process automation system, suitable for standardized production.

Case: Cross-sea bridge construction projects require continuous supply of large quantities of concrete, and the stationary mixing plant can guarantee a stable supply.

Scenario: Urban construction, municipal projects and other scenarios that require centralized supply of concrete.

Advantages:

Scale production: Professional concrete mixing plants can be established to unify production and distribution and improve resource utilization.

Controllable quality: Stable quality is ensured through real-time monitoring of concrete performance.

Reduced pollution: Centralized production reduces site dust and noise, in line with urban environmental requirements.

Cases: Urban high-rise building complexes, subway construction and other projects that rely on the supply of commercial concrete mixing plants.

Scenario: Large-scale factories, power stations, mines and other sites requiring long-term construction.

Advantages:

Cost-effectiveness: Low cost for long-term use after one-time investment, suitable for projects with sufficient budget.

Customized Configuration: Special mixing hosts can be configured according to project requirements.

Permanent foundation construction: The fixed mixing plant is rooted in its solid permanent concrete foundation. The concrete foundation needs to be poured, and the equipment is rigidly connected to the ground for smooth operation and strong vibration resistance.

Modularized steel structure system: The main structure of the mixing plant adopts high-strength modularized steel structure. For example, the batching machine, mixing machine, powder bin, screw conveyor, belt conveyor, etc. are prefabricated into standardized steel component modules. These modules are precision machined and pre-assembled in the factory, and then transported to the site for quick assembly and installation.

High degree of integration: The various process links and auxiliary equipment required for concrete production are highly concentrated and integrated in a compact and orderly space. The integrated PLC control system realizes the automatic adjustment of parameters such as raw material proportion, mixing time and discharging speed, forming a complete, efficient and closed-loop production system.

Wide range of theoretical production capacity: The theoretical production capacity is from 60-240m³/h for belt type, and from 25-75m³/h for bucket type: the stationary mixing plant has a strong production capacity, and its theoretical hourly production capacity has a wide range, which is able to meet the different requirements of different scale projects and market demand.

Continuous production process: Through optimized batching and mixing procedures and efficient equipment performance, under the premise of guaranteeing the quality of concrete, the stationary mixing plant is able to achieve rapid cycle work, ensuring that concrete can be supplied continuously and stably according to batches.

Measuring accuracy ±1%: The stationary mixing plant is equipped with a high-precision measuring system to accurately weigh various raw materials such as sand, stone, cement, fly ash, mineral powder, water, additives and so on. Its metering accuracy can usually reach within ±1% (the metering accuracy of some key materials such as cement and additives is even higher).

Dual-unit parallel design: Configure two sets of relatively independent mixing mainframe and its supporting batching and metering system, and share part of the raw material storage silo and finished product discharging system. The double sets can realize the mode of standby replacement.

Totally closed environmental protection system: Equipped with pulse dust collector to efficiently filter the dust from batching, mixing and discharging, adopting soundproof cover, low-noise motor and vibration-damping foundation to maximally control the impact of hazardous substances on the surrounding environment.

Intelligent control system: High-performance industrial computer system as the core, equipped with friendly human-machine interactive interface. Intelligent control from formula management, automatic batching, automatic mixing to automatic discharging, with a variety of advanced functions such as production data collection and analysis, real-time monitoring of equipment status.

Long life: The steel structure main body is designed to last for more than 15 years with low maintenance cost.

Optimization of energy consumption: Adopting high-efficiency motor and frequency conversion technology, the energy consumption per unit of production is 10%-15% lower than that of mobile type.

High residual value: The equipment can be disassembled and relocated to new construction sites, with a high rate of maintenance of second-hand market value.

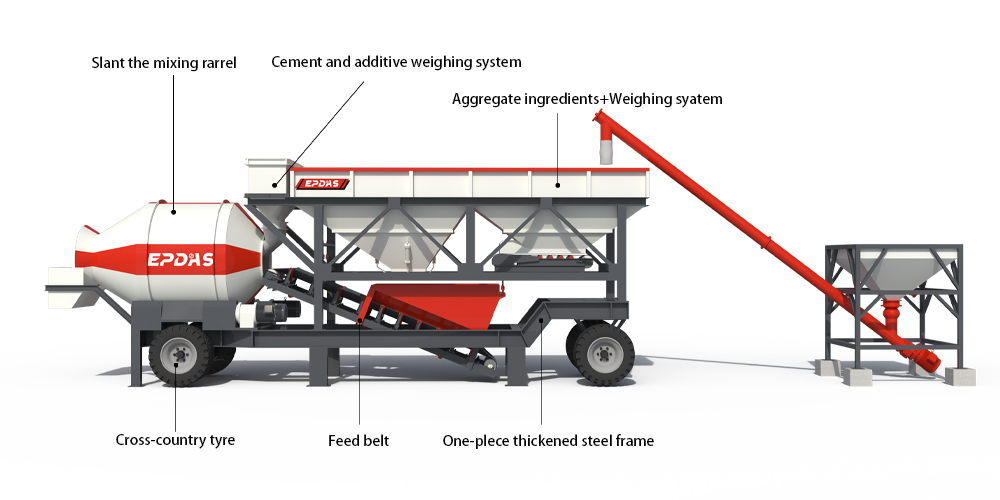

Mobile Concrete Batching Plant is a concrete preparation equipment integrated with trailer or towing structure, which consists of a modular unit of mixing machine, material conveying system, weighing system and control system.

This equipment has the technical characteristics of quick transfer, foundation-free installation and so on. It has the remarkable features of small footprint and easy mobility, and is designed for flexible operation scenarios. EPDAS offers two main models of mobile concrete mixing plants, YHZM concrete batching plant series and MCBP batching plant series, which meet the needs of different projects in terms of flexibility and production capacity. Both models have good mobility and excellent mixing results.

As a portable, efficient and reliable concrete production equipment, the Mobile Batch Plant highly integrates raw material storage, weighing, conveying, mixing, discharging and a fully automated control system in a mobile frame, realizing the function of batch production of concrete at any site. Its production capacity covers a wide range, from 25 m3/hour to 100 m3/hour, and some advanced models with double chassis design can even reach 120 m3/hour or more, which can meet the needs of medium-sized projects.

Mixing machine: small double horizontal shaft forced mixer is mostly used, such as YHZM JS500-JS1000 models, MCBP JZM500-JZM2000 models. The mixing machine is rigidly connected with the chassis to adapt to the complex working environment in the field and ensure the stability of the mixing work.

Material Weighing System

Integrated design: The weighing hoppers for aggregate, powder and liquid are compactly arranged on the same frame, and this design greatly saves space and can meet the production requirements of ordinary concrete.

Simplified function: In terms of aggregate weighing, a single group weighing method is mostly adopted, i.e. sand and stone mixing and weighing; powder and liquid share a set of pipeline, and the delivery of different materials is controlled by switching valves, which simplifies the structure of the equipment and the operation process.

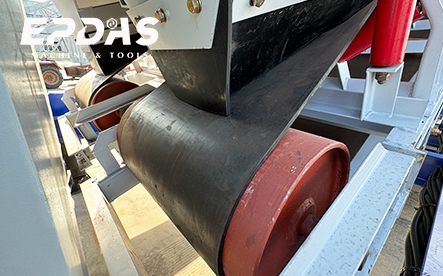

Material Conveying System

Aggregate conveying: Short-distance belt conveyor or lifting hopper, can be directly taken from the ground or docked to a small silo, the conveying method is flexible and simple.

Powder conveying: Equipped with small screw conveyor, connected with movable cement silo to realize stable conveying of powder.

Liquid conveying: Using small water pump and admixture pump, the conveying pipeline is short and collapsible, which can reduce the space occupied during transportation and facilitate the movement of the equipment.

Material Storage System

Aggregate silo: Adopts folding design, which can be folded up during transportation to reduce space occupation; for ultra-small mobile mixing plant, direct manual loading can also be adopted.

Cement silo: It is a trailer-type cylindrical silo with a towing device, and its arch-breaking device is relatively simplified.

Admixture tank: Mostly small plastic tanks, integrated next to the main machine, which need to be manually stirred to prevent the admixture from settling.

Control system: It is composed of simple PLC and touch screen (or button control), supporting semi-automatic production mode, and requires manual activation of part of the production process. It is capable of storing a small amount of concrete proportioning program, and also has basic fault alarm function, which is convenient for operators to find and deal with problems in time.

Mobile chassis and ancillary facilities: It adopts tire or tracked chassis, equipped with hydraulic legs, which can stably support the equipment during operation and adapt to different terrain conditions. The ancillary facilities are relatively simplified, the air circuit system uses a small air compressor; the dust removal system is mostly a simple filter bag, which can play a certain role in dust prevention.

Scenarios: rural road construction, small-scale water rehabilitation, temporary bridge repair, etc.

Advantages:

Rapid Deployment: Modular design, can be installed and disassembled within hours.

Flexible relocation: Relocate with the progress of the project to avoid idle equipment.

Low site requirements: Adapt to narrow or complex terrain, such as mountains, swamps, etc.

Scenario: remote mountainous areas, deserts, islands and other areas without fixed concrete supply.

Advantages:

Self-sufficiency: on-site production of concrete reduces dependence on external facilities.

Strong emergency response capability: rapid restoration of infrastructure after natural disasters (e.g. earthquakes, floods).

Scenarios: small construction sites, agricultural irrigation, yard renovation, etc.

Advantages:

Economical and efficient: avoiding the high investment and site occupation of stationary mixing plant.

Simple operation: manual or semi-automatic control, suitable for non-professional teams.

Modular quick-assembly design: core components are precision prefabricated and debugged in the factory, and only simple splicing through standardized interfaces is required for on-site installation, which shortens the installation cycle.

Containerized Transportation Unit: The whole unit adopts the international standard containerized transportation unit design, and each functional module (such as the mixing main unit, batching silo unit, cement silo unit, etc.) conforms to the containerized transportation size specification for marine transportation.

Foundation-free installation: Foundation-free installation technology is realized, through adjustable legs and temporary counterweight system, the equipment can be directly and stably placed on the hardened ground or steel plate platform after simple leveling.

Theoretical production capacity 25-100m³/h: Depending on the model, the theoretical production capacity covers the range of 25-100m³/h, which can meet the diversified concrete demands from small infrastructure construction in rural areas to large-scale building construction in urban areas.

Intermittent production process: the whole production process including aggregate metering, cement and fly ash powder metering, water and admixture metering, mixing, discharging, etc. is carried out intermittently in sequence to ensure the uniformity of concrete mixing.

Compact design of single unit: in terms of space utilization, through optimizing the space layout and integrated design of each functional module, the floor space is reduced by 30%-50% compared with the traditional mixing plant.

Expandable Configuration: Value-added modules such as full-automatic control system, concrete conveying pump, and automatic replenishment system for aggregate silo can be flexibly installed according to the actual demand.

| Structural Components | Stationary Batching Plant | Portable Batching Plant |

| spatial Arrangement | Multi-storey main building structure with dispersed and fixed equipment and a large footprint | One-piece rack, compact equipment integration, can be moved as a whole |

| Capacity and Scale | Capacity 60-240m³/h, suitable for large projects | Capacity ≤ 50m³/h, suitable for small temporary works |

| Storage Capacity | Large-capacity silos (large capacity for aggregate and cement silos) | Small capacity removable silo for frequent replenishment |

| Degree of Automation | Fully automatic control, high precision, support networking | Semi-automatic, lower precision, simplified function |

| Mobility | Fixed installation, cannot be moved | With tire chassis and towing device for quick transfers |

| Affiliate System | Improvement (specialization in dust removal, air circuits, cleaning systems) | Simplified (meets basic functionality, low cost) |

Stationary concrete batching plants are characterized by stable production capacity, accurate metering and long-term benefits, making them suitable for large-scale projects, fixed sites and high-specification concrete needs; while portable mixing plants, with their rapid deployment, flexible relocation and low initial investment, have become the preferred choice for short-term projects, decentralized work and emergency scenarios.

For project managers, the core of the choice lies in matching the equipment characteristics with the project requirements, weighing the project scale, duration, budget range and site conditions, and selecting the mixing plant that suits the actual project.

Want your construction project to have the quality concrete it deserves? Contact EPDAS and we’ll explain the various types of mixing plant solutions and get you a quick, customized quote! Our professional team will recommend the most suitable mixing plant for your project. A thorough understanding of the functions and advantages of the mixing plant can help make a wiser choice.

If you are planning to upgrade your construction capacity, you might as well learn about our concrete mixing plant and related machinery series. Whether it’s pursuing process simplification to enhance efficiency or adhering to top quality standards to ensure safety, our all-round solutions can meet all these needs.